Kinemic Tool

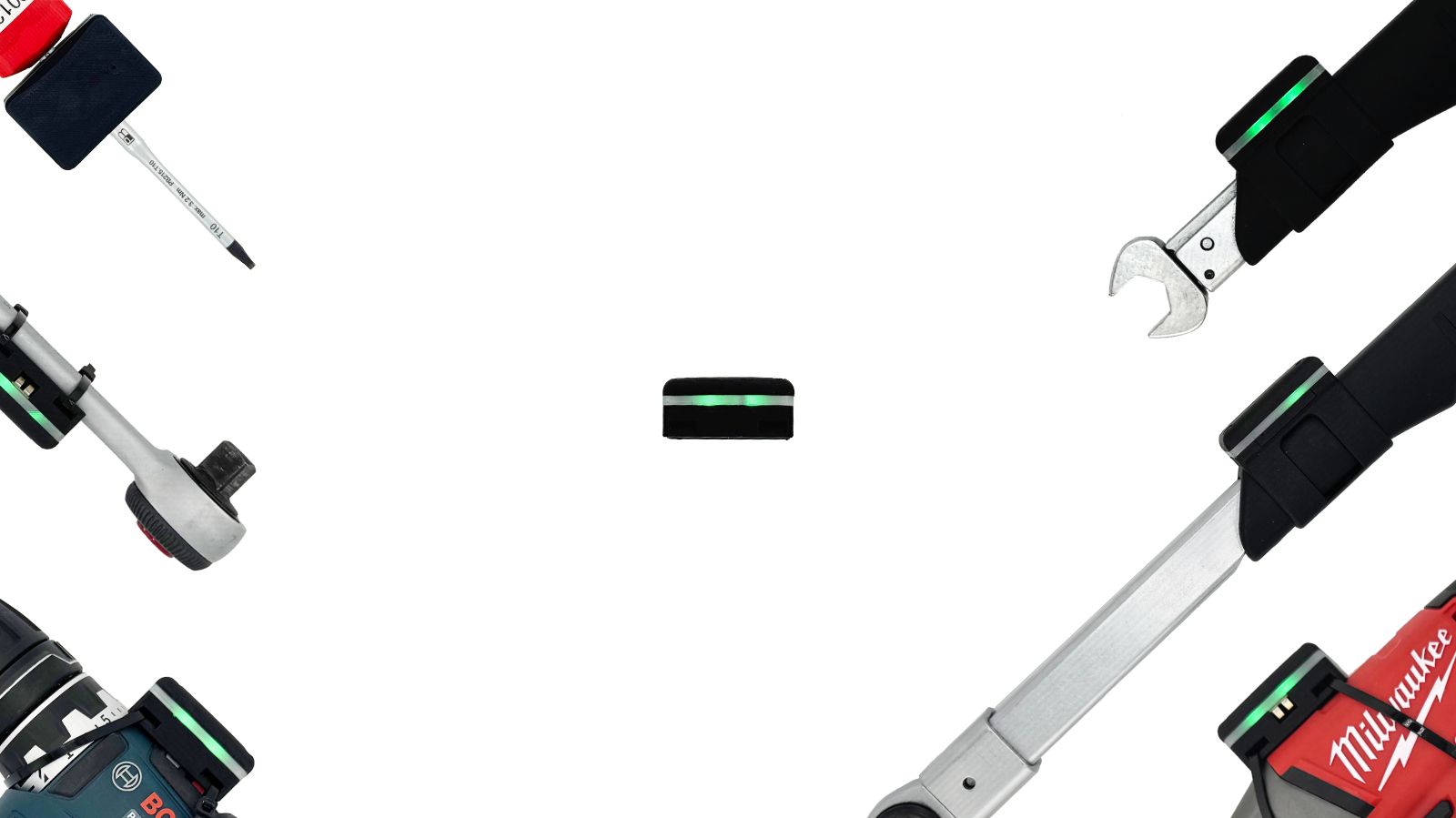

Kinemic Tool is an AI-based Attachable that’s easy to mount on existing tools. It detects tool events and is Wifi-connected.

Torque wrenches and drivers, cordless screw drivers and other tools for manual assembly processes can be equipped with the system.

Kinemic Snap

Kinemic Snap uses a Wearable or a Magnet-Clip-On and cutting-edge AI-processing to reliably detect plugged and clipped connections and fasteners.

Secure critical assembly processes, finally!

Kinemic Band

Kinemic Band is a gesture control wearable that allows interaction with digital devices using just simple hand movements.

Kinemic Build

Kinemic Build is our worker assistance software, enabling Kinemic Tool, Kinemic Snap and Kinemic Band.

Kinemic Build can be used on its own – even with just a button. But where would be the fun in that?

If you already have a leading system (e.g. ERP/MES), Kinemic Build can simply forward what you want to know, thanks to its open interface.

Kinemic offers advanced solutions for the Digitization and Optimization of assembly processes, especially for plugging connectors and torque wrenches / screw drivers.

Make your production line smart.

Our Approach

We develop innovative Wearables, Attachables and Hardware to make assembly processes easier and better. Data from our hardware is the input for our AI models.

We integrate data protection and digital rights from the start.

Our servers are based in Germany, our developers are, too. The company is 100% owned by the founders.

This enables us to guarantee independent, transparent and secure systems. Using open standards and interfaces, our software is interoperable and future-proof.

Further Services

Development of innovative IT-Systems

Together with our customers we develop new powerful applications, research new concepts and bring innovations to life.

Whether AI, UI/UX or Hardware: We are your competent service provider.

Please contact us to discuss your requirements!

Reference projects

For and with a leading German stationery producer we’ve devised AI-enabled software to recognize handwriting using customer-provided hardware. We’ve researched and developed the AI system as well as a backend engine, supporting and orchestrating large-scale go-live across different countries. The system has several thousand users per day. Current project.

For a leading German tool manufacturer we’ve developed and iterated a full-fledged UX for an innovative assistant system, enabling improved machine operation, higher utilization and fewer errors. We’ve integrated and extended customers’ CI requirements where necessary. Completed project.

In a research project for vertical farming we’re developing an AI setup to determine plant health and have taken on consulting and service tasks. Current project.

Awards